Temperature Controllers - By Size

The following list of temperature controllers is organised by size to help our customers get to the product they need fast.

- From Basic ON/Off to Multi Zone capability

- Pricing starts from £85

- We assist with setup over the phone for all product sold

- We add value by using control features to reduce wiring and control panel cost

Fuji Electric PXF4Temperature Controllers 48mm x48mm |

|

|

Fuji Electric PXF5Temperature Controllers 48mm x96mm |

|

|

Fuji Electric PXF9Temperature Controllers 96mm x96mm |

|

|

|

||

Fuji Electric PXR348mm x 24mm Temperature Controllers |

|

|

Fuji Electric PXR448mm x 48mm Temperature Controllers |

||

Fuji Electric PXR548mm x 96mm Temperature Controllers |

|

|

Fuji Electric PXR996mm x 96mm Temperature Controller |

|

|

Fuji Electric PXELow cost 48mm x 48mm Temperature Controllers, perfect for OEM applications. |

|

|

Fuji Electric PXR Range OverviewPXR series of temperature controllers offer a ultra reliable and cost effective solution flexible enough for most temperature applications. On/off, PID or Fuzzy Logic control is available. |

|

|

GuideIf you are unsure which temperature controllers is right for you, our guide will help you getting the right unit. |

|

|

Obsolete Fuji ControllersFuji Electric make it easy to upgrade to a new model. Check out our interactive equivalence table to see which model you need to replace your old temperature controller. |

|

|

|

||

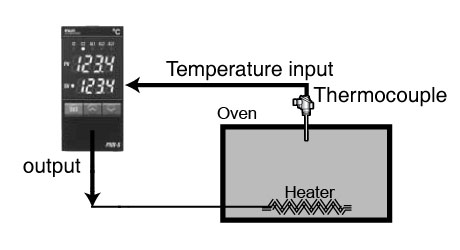

What is a Temperature Controller and how does it work?

A temperature controller is an instrument used to control temperature. It does this by comparing the process temperature (process variable) with the desired value (set value). The difference between these values is known as the error (Deviation). Temperature controllers use this error to decide how much heating or cooling is required to bring the process temperature back to the desired value. Once this calculation is complete the controller will produce a signal that effects the change required. This output signal is known as the manipulated value and is normally connected to a heater, control valve, fan or some othe "final control element" which actually injects or removes heat from the process.

Temperature controllers form one of the four parts of a temperature controlled system. To help visualize this we will consider an oven. The four parts would be :

1 The oven

2. The heater

3. The thermometer

4. The controller

The role of the temperature controller is to measure the temperature on the thermometer, compare it to the set point and to calculate the amount of time the heater should remain switched on to maintain a constant temperature.

Many factors change the amount of time that the heater needs to maintain the process temperature. For example the size of the heater, the size of the oven, the amount of insulation surrounding the oven and the ambient temperature are some of the more obvious. But other factors such as the circulation of air within the oven, the humidity of the air. The mass of product being place inside the oven and many more that are described in minute detail at https://newton.ex.ac.uk/teaching/CDHW/Feedback/OvSimForm-gen.html

At the end of the day a temperature controller replaces the function of a person who's job description would read something like:-

Watch that thermometer

Keep the temperature stable at 80Deg C

If you need more heat, switch on the heater.

The important point, is that the temperature controller has one input, one output and one set point.

Temperature controllers are used, on Ovens, furnaces, plate heat exchangers, incubators, kilns, stills, vats, cooking pans and vessels. They are key in the manufacturing process of food, beverage, cooking, pottery, beer, wine, pharmecuticals , oil gas, heat treatment, sterilisation, pasturisation, plastic and many many more.

Simple low cost temperature controllers add value to many factory applications. When they are used correctly they can can save money, lower your CO2 foottprint and help toward UK net zero