Temperature controller questions and answers.

Q: What is a Temperature Controller and how does it work?

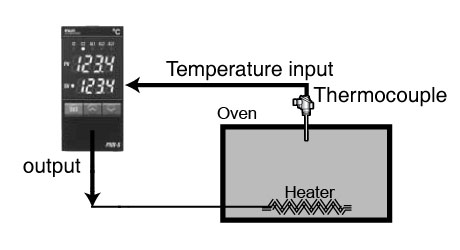

A : A temperature controller is an instrument used to control temperature. It does this by comparing the process temperature (process variable) with the desired value (set value). The difference between these values is known as the error (Deviation). Temperature controllers use this error to decide how much heating or cooling is required to bring the process temperature back to the desired value. Once this calculation is complete the controller will produce a signal that effects the change required. This output signal is known as the manipulated value and is normally connected to a heater, control valve, fan or some othe "final control element" which actually injects or removes heat from the process.

Temperature controllers form one of the four parts of a temperature controlled system. To help visualize this we will consider an oven. The four parts would be :

1 The oven

2. The heater

3. The thermometer

4. The controller

The role of the temperature controller is to measure the temperature on the thermometer, compare it to the set point and to calculate the amount of time the heater should remain switched on to maintain a constant temperature.

Many factors change the amount of time that the heater needs to maintain the process temperature. For example the size of the heater, the size of the oven, the amount of insulation surrounding the oven and the ambient temperature are some of the more obvious. But other factors such as the circulation of air within the oven, the humidity of the air. The mass of product being place inside the oven and many more that are described in minute detail here.

At the end of the day a temperature controller replaces the function of a person who's job description would read something like:-

Watch that thermometer

Keep the temperature stable at 80Deg C

If you need more heat, switch on the heater.

The important point, is that a basic temperature controller has one input, one output and one set point.

Q: What do I need to know when choosing a temperature controller?

As discussed above, the temperature controller is only one part of the temperature controlled system, and accurate control is a function of all of the elements correctly playing their part

To ensure reliable control, controller needs to know the true temperature. So the first thing we need to know is what type of temperature probe is being used in the system. This will be the input to the controller.

We also need to consider what the controller is going to be connected to, so that it can change the temperature. Will it be a heater that can be switched on and off, if so, how much current (in amps) will the heater use. If it is a large heater there may be the need for a solid stare relay or contactor. Alternatively the heat may be supplied via a control valve (as in steam systems). Knowing this will allow the user to choose between three different output types. Relay output , Solid State relay drive (SSR output) and 4-20mA.

How accurately you want to control the temperature will effect the type of temperature controller that you choose. Three basic types are normally considered: On/Off Control, PID Control and Fuzzy Logic control.

Tip: The Fuji PXR Temperature Controller is an ideal controller for most temperature application. For more demanding applications (higher accuracy, more digital input/output, Universal input) we recommend the Fuji PXG Process Controller.

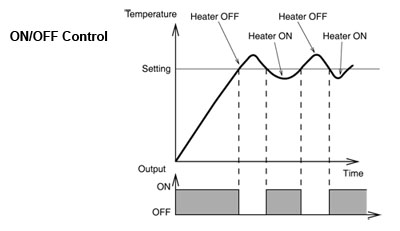

Q: What is On/Off Control

On off control is like operating a switch. This type of temperature controller will turn on the heat when the process variable is below the set point and turn it off when the process variable is above the set point. These controllers normally include a delay, hysterisis and or a cycle time to reduce the cycling or "hunting" when the process variable is close to the set point.

Tip: The Fuji PXE and the Fuji PXR Temperature Controller can be used as a simple On/Off controller by setting the P, I and D values to 0.

Q: What is Proportional Control

Proportional controls are designed to eliminate the cycling associated with on-off control. A proportional controller decreases the average power used by the heater as the temperature approaches setpoint. This has the effect of reducing the heat that is added to the process so that the temperature approaches the setpoint without overshoot. This proportioning action can be accomplished by turning the output on and off for short periods of time.

This "time proportioning" varies the ratio of "on" time to "off" time to control the temperature. This is sometimes refered to as Pulse width modulation (PWM). The proportioning action occurs within a band either side of the set point. Outside this band (proportional band) , the controller functions as an on-off unit, with the output either fully on (below the band) or fully off (above the band). However, within the band, the output is turned on and off in the ratio of the measurement difference from the setpoint. At the setpoint (the midpoint of the proportional band), the on-time and off-time are equal. If the temperature drops below the set point, the on time becomes longer. If the temperature is above the set point, the off time will be longer.

Tip: The Fuji PXE and the Fuji PXR Temperature Controller can be used as a proportional controller by setting the I and D values to 0.

Q: What is PID Control

The third controller type provides proportional with integral and derivative control, or PID. This controller combines proportional control with two additional adjustments, which helps the unit automatically compensate for changes in the system. These adjustments, integral and derivative, are expressed in time-based units; they are also referred to by their reciprocals, RESET and RATE, respectively. The proportional, integral and derivative terms must be individually adjusted or "tuned" to a particular system using trial and error. It provides the most accurate and stable control of the three controller types, and is best used in systems which have a relatively small mass, those which react quickly to changes in the energy added to the process.

It is recommended in systems where the load changes often and the controller is expected to compensate automatically due to frequent changes in setpoint, the amount of energy available, or the mass to be controlled.

Fuji Electric offers a number of controllers that automatically tune themselves. These are known as autotune controllers.

Tip: Any Fuji Electric Controllers can achieve quality PID control. We recommend the Fuji PXE for OEM applications, the Fuji PXR Temperature Controller for most standard temperature application and the Fuji PXG Process Controller when extra accuracy and features are required.

Q: What is Fuzzy Logic:

Fuzzy Logic is a simple way to arrive at a definite conclusion based upon vague, ambiguous, imprecise, noisy, or missing input information. In short 'Fuzzy Logic' attempts to mimic human thought process.

A temperature controller working with Fuzzy Logic would compare the actual temperature with the set point to establish how far from the set point the temperature is. Then using predetermined rules, the controller would add more or less heat. By monitoring how fast the temperature changes for a give output change, the controller can use other rules to modify its response.

It is very robust and forgiving of operator and data input and often works when first implemented with little or no tuning.

With Fuzzy Logic, the control output is smooth, despite a wide range of input variations.

Defined rules means that is specifically designed for the process type, i.e. large system lag of temperature systems.

Fuzzy Logic can control nonlinear systems that would be difficult or impossible to model mathematically.

Tip: Fuji Electric Controllers are all able to achieve quality Fuzzy Logic control. We recommend the Fuji PXR Temperature Controller for most standard temperature application and the Fuji PXG Process Controller when extra accuracy and features are required.

Standard Sizes

Since temperature controllers are generally mounted inside an instrument panel, the panel must be cut to accommodate the temperature controller. In order to provide interchangeability between temperature controllers, most temperature controllers are designed to standard DIN sizes. The most common DIN sizes are shown bellow:

|

(from left to right) Size 9 Size 7 (not shown) Size 4 Size 3 |

|

Tip:

The Fuji PXE temperature controller is available in size 4 and is extremely compact.

- The Fuji PXR Temperature Controller is available size 3, 4, 5, 7 and 9. See Fuji PXR3, Fuji PXR4, Fuji PXR5, Fuji PXR9 and please contact us for Fuji PXR7

- The Fuji PXG Process Controller is available size 4, 5 and 9.

- The Fuji PXH high performance process controller is available size 9.

Next | |

Features ComparisonCompare the feature of our range of Fuji Electric Temperature and Process Controllers |  |

Back to

Controllers Page Ready to choose the right Temperature /

Process Controller? |  |

Back to Controllers GuideBack to controllers guide and controllers questions and answers page. Also don't forget that we are always happy to help so if you have any specific question please feel free to contact us! |  |